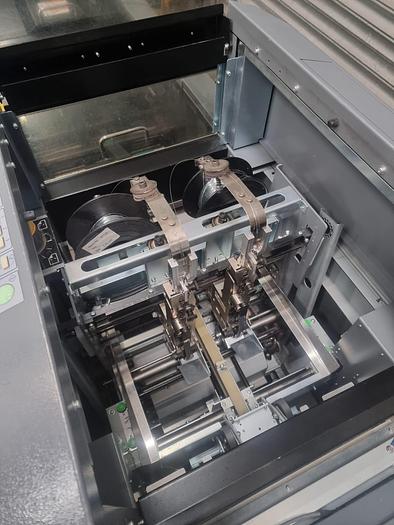

Duplo system 350 Crease Digital feeder, Fold, Stitch , Trim

Duplo system 350 Crease Digital feeder, Fold, Stitch , Trim

Location:Lancaster, United Kingdom

Description

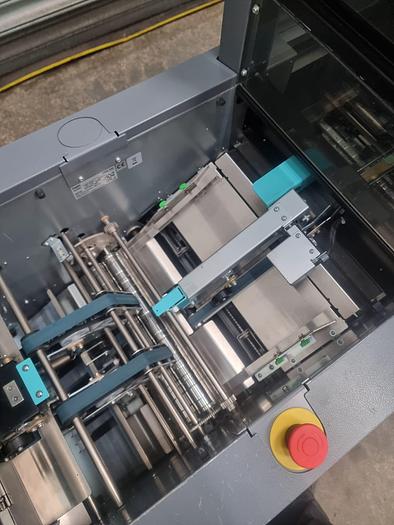

Duplo’s near-line DFS-3500 Bookletmaking System has been designed to completely finish full-bleed booklets in a single pass. Combining the creasing and slitting functions of the DC-446 Creaser with the stitching, folding, and trimming capabilities of the mid-range DBM-350/T Bookletmaker and Trimmer, the DFS-3500 delivers an affordable all-in-one bookletmaking system ideal for short-run applications.

By automating the finishing process required to create full-bleed booklets, the DFS-3500 eliminates the need for a separate guillotine cutter and creasing machine. Time consuming set-ups, wasted material, and turnaround times are all reduced.

Complete job set-up is done from the user-friendly DC-446 control panel and up to 30 jobs can be saved for

quick and easy recall. The DFS-3500 Bookletmaking System’s ability to slit, crease, stitch, fold, and trim in one pass makes it the perfect solution for producing applications such as calendars, catalogs, yearbooks, newsletters, and more.

SUPERIOR, HIGH CAPACITY FEEDING

With a 4-inch stack capacity and top feeding air suction technology, the DFS-3500 enables users to run a productive bookletmaking operation. The sheets feed from the top of the stack to reduce scratching commonly caused by bottom feeders and the high-capacity feeder means the system can run for a longer period of time without constant reloading.

To ensure the accuracy of each booklet, the DFS-3500 uses a double feed detection sensor to stop the machine when it detects two or more sheets have been fed.

IN-LINE CREASING AND SLITTING

- Creasing the cover and innermost sheets prior to folding prevents toner cracking and guarantees crisp, professional folds. The optional slitting module trims the head and foot of each sheet for a full-bleed trim before it accumulates in the booklet maker. The margins are deposited into a bin located underneath the bridge unit. By slitting in-line, operators are no longer required to pre-cut the sheets on a separate guillotine cutter, resulting in decreased downtime and increased productivity.

- 3,000 booklets an hour

- Built in spine press for lay flat booklets

- 20 set up programs

- Up to 60 collating bins

- Hand feed for covers or pre-collated sections

- Suction feed with air management system copes with tricky papers

- Stacker delivers offset stacks for job separation at 10,000 sets an hour

- Jogger for delivering sections for different finishing options

- Easy to follow touch screen control

- Continuous loading for non-stop operation

BOOKLET MAKING SYSTEM SPECIFICATIONS

Input Paper Size

Saddle Stitch and Fold or Fold Only

Side and Corner Stitch

5.82” x 8.27” to 12.6” x 18.11”

7.17” x 10.12” to 8.5” x 11.69”

Paper Type Coated, uncoated, UV coated

110-350 gsm

Number of Sheets 1-20 sheets

Number of Stitches 1-2

Margin Slits 4mm to 55mm

Feed Capacity 3.9” (100mm)

Specifications

| Manufacturer | Duplo |

| Condition | Used |

| Stock Number | 2562 |